Back to Bike.

Improving a Thule 990

|

by Jérôme Daoust. Revised 2009/9/11 |

Main (Top of Page)

These modifications relate to the Thule 990 bike rack. Manufacturer info:

For normal bikes (no batteries, motor...) this bike rack would probably have provided enough stiffness to limit the amplitude of movement while they sit on the rack. But when considering electric bikes, typically weighing over 50 lb (22.7 kg) each, it was worth stiffening this bike rack.

The purpose of this project was to reduce the amplitude of relative movement (with respect to the car) of the bikes on the rack. There are 3 primary relative movements of the bikes (ignoring the front/rear movement of the top of the bikes with respect to their cradles):

- Bounce. Up/Down movement.

- Sway. Side movement.

- Twist. Rotation about the car's axis.

This was accomplished by relocating the position of the bikes to be as close to the hitch receiver as possible, while avoiding contacts with the vehicle. Doing so had the following cumulative effects:

- Reduced cantilever load. The mass of the bikes have less leverage onto the hitch receiver. For a given rack stiffness, this helps reduce both the relative bounce and sway motion of the bikes.

- Increased rigidity of the rack.. The shorter backbone and hitch tubes are stiffer because they are shorter.

Hitch (Top of Page)

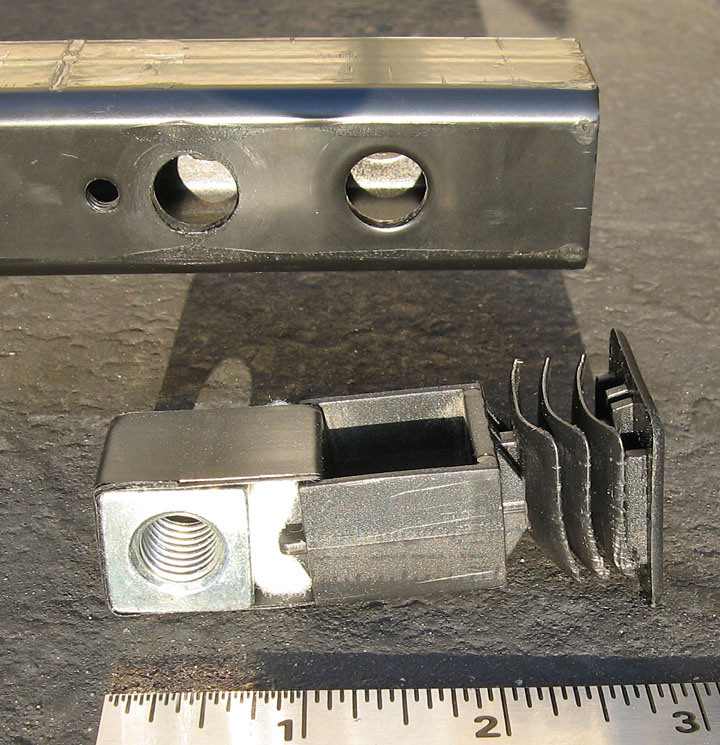

In the picture below, the left large hole is new and serves to secure the hitch to its connector. Similar to the original one on the right, it has a diameter of 0.5". This new hole is 1.125" from the original location. The new square tube hole was drilled with a 0.5" diameter bit on a drill press. Holes were reamed inside/outside to remove sharp edges. So the effective length of the hitch will be reduced by this same amount, and we will simply have it insert deeper into the receiver, which is also beneficial to reduce potential free play. The position of the new hole was a compromise between:

- Maximizing the effective shortening effect, so being furthest away from the original hole as possible.

- Keeping enough clearance between the vehicle's bumper to the carrier's hinge plates. 0.5" was kept in the case of a 2008 Suzuki SX4 crossover.

- Not being too close to 2" hitch receiver adapter positioning hole (leftmost smaller hole in picture below).

For the square nut inside the hitch to be aligned with the new hole (picture below), it was taken out of its square receptacle and attached further from the plug (above picture).

Free play in the carrier's assembly is bad because it allows relative motion between the parts, which then receive a shock with larger accelerations when the play is exhausted. As a counter-example: Imagine not having airbags in your car and hitting the steering wheel and dash. In the case of my vehicle some free was eliminated by inserting a shim between the top of the hitch and the receiver (2 pictures bellow), simply held by tape (because there are no forces to "squirt out" the shim).

Having relocated the hitch further into the receiver has 3 beneficial effects:

- Reduced effective length (behind the receiver), helps:

- Increase stiffness.

- Reduced leverage from the bike's mass.

- Reduce free play from the longer insertion into the receiver

Backbone (Top of Page)

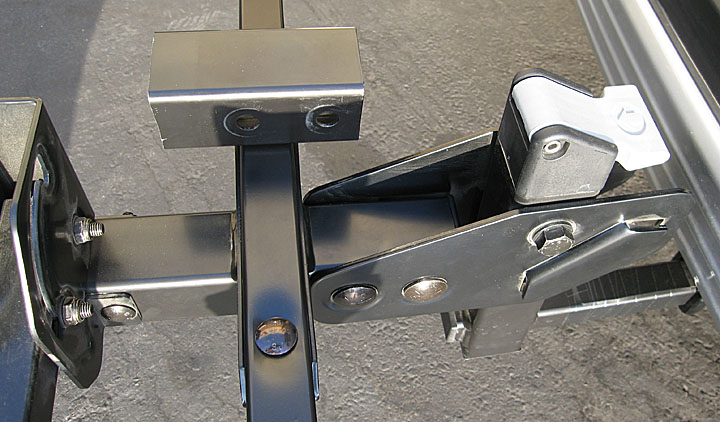

The backbone was cut such that the closest horizontal carrier tube weld is next to the ends of the hinge vertical plates (picture below, which also shows the cut section of the backbone). To establish the position of the new holes, these steps were followed:

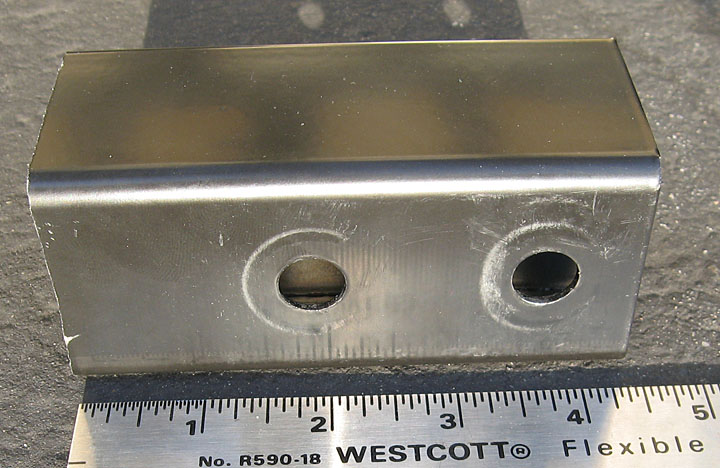

- Measured the length of the backbone, which is in between the vertical plates of the hinge, added about 5mm of extra length to reduce clamping deformation of the tube side walls at the hole closest to the tube end. This was 9.5 cm (3.75"). The tube was cut to leave that length from the weld of the closest horizontal carrier tube. Cut section (2 pictures down) was about 4.5" long.

- To establish the position of the new holes, the hinge vertical plates were slipped over the shorter backbone tube end and length positions were marked. With the hinge plates slipped off, the final hole center locations were set such that they pass by the center of the square tube walls. The new holes were drilled with a 0.5" diameter bit on a drill press. Holes were reamed inside/outside to remove sharp edges. Compared to the original hole locations, there are offset by about 4.75", and this is the corresponding effective length reduction of the backbone.

Picture below (and above) show the cut section (about 4.5" in length) of the backbone.

Preventing the backbone walls from crushing deformation...

With the original length of the backbone I noticed there was some friction play between the plates of the hinge an the backbone, so I further tightened the 2 bolts squeezing the backbone tube side walls. Although it helped reduce the free play by increasing friction, the side walls of the square tube were deforming. To prevent this from happening to the sidewalls near the new holes, internal spacers were added to pick up the compression load of the bolts. So those 2 bolts could now be tightened more than before and free play nearly eliminated in that area.

Conclusion (Top of Page)

Measuring the improvement...

· We now have a distance of approximately 18" between the middle of the horizontal carrier tubes and the hitch receiver.

· Before that distance was greater by 1.125" (hitch) and 4.75" (backbone) thanks to their effective shortening.

So the new length is 75% of what it was:

· 0.75 = 18 / ( 18 + 1.125 + 4.75 )

Effects:

· Bouncing and sway motions of the bikes. Using the following formula, we know that maximum deflection (amplitude of movement where the bikes are) is dependant on the cube (3rd power) of the effective length of the hitch and backbone:

|

|

So the new maximum deflections (bouncing and sway of the bikes) will be 42% (0.753) of what they were before. So less than half of what it was before. Also, the effect of reduced free play (Shimming the hitch; tighter bolts sandwiching the hinge plates and backbone) can only be beneficial.

· Twisting motion of the bikes. The maximum rotations will be 75% of what they were, because it proportional to the length variation.

· Strength of the carrier. The strength (or safety factor) is inversely proportional to the stress the carrier is subjected to, and we can assume that these are proportional to the leverage (bending force) from the bikes' mass because the hitch and backbone cross sections have not changed. So the new strength is 1.33 (1/0.75) times greater than before. Another way of appreciating this is to think that the original manufacturer's load limit of 70 lb, is now bumped up to 93 lb, placing it closer to what 2 electric bikes will total.

· Access to the vehicle's rear cargo compartment. There is still enough room to walk between the rear bumper and the closest horizontal carrier tube.

Further modifications:

· 2008/11/28:

I had my aftermarket class 1 hitch receiver (limited to that on a Suzuki SX4)

modified into what would probably be a class 2.5, by having a professional

welder add a steel tab between the end of the receiver (near the receiver

opening) and the car's frame to eliminate the up/down flexibility. And I had

the welder reinforce the rack itself by adding a 2" plate at the inside

corner of the horizontal bar that leaves the hitch receiver and the vertical

bar. In attachment is a sketch of where the latest mods were added (in red).

End result...

o I can step onto the bike carrier with my 170 lb (77 kg) and the carrier does not have obvious flex.

o When I carry 110 lb of ebikes on it, it can take big bumps and the bikes don't bounce more than the car.

Related discussions: